⚗️ Small-Scale Bioprocessing — 3 L, 10 L & 50 L Benchtop Systems

Our benchtop bioprocess facility bridges the gap between R&D and pilot scale. We provide end-to-end support for runs ranging from 3 L to 50 L,

This scale is perfect for process refinement, media comparison, cell expansion, and preparing tech-transfer packages for larger volumes.

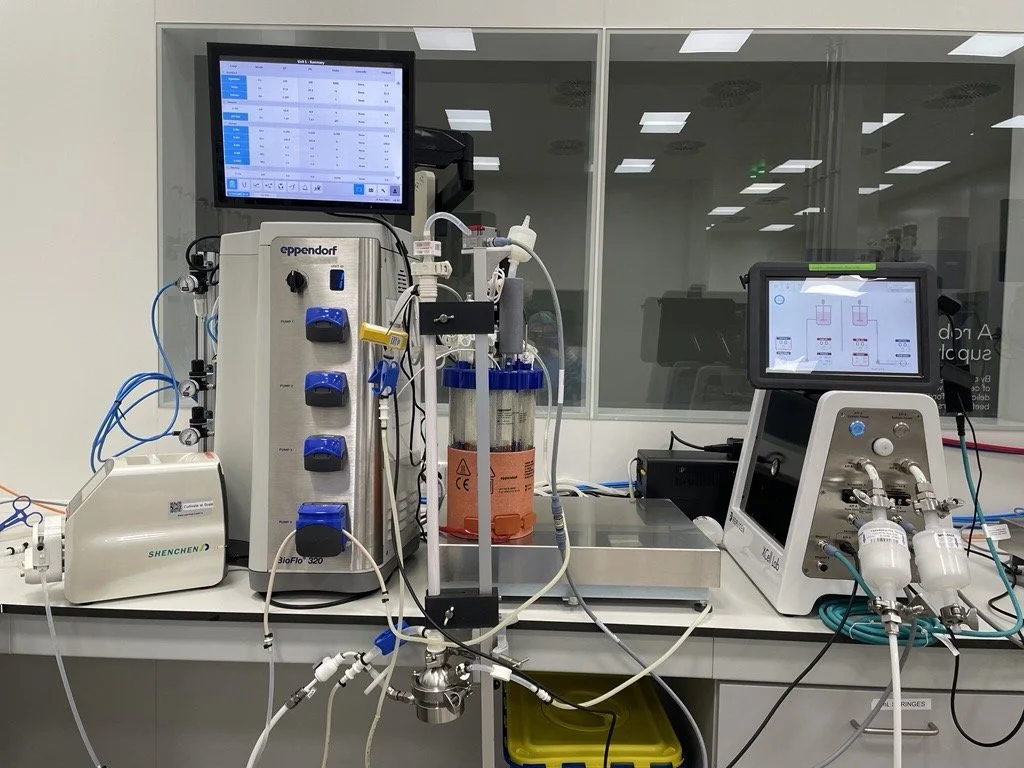

3L bioreactor

3L & 10L bioreactors

Small-scale 3 L and 10 L bioreactors are typically used during early process development to optimize parameters such as seeding density, feeding strategy, agitation, and gas transfer under controlled conditions. These volumes allow rapid iteration, lower material costs, and efficient comparison of multiple conditions in parallel.

Harvest of a 50L bioreactor

50L bioreactors

Once the process is optimized, it is transferred to a 50 L bioreactor, which serves as an intermediate pilot scale. At 50 L, our engineers validate scalability, confirm process robustness, and generate larger quantities of material for downstream testing or product development. This step ensures that the process behaves reliably before moving to full production-scale bioreactors.

ATF perfusion system in 3L bioreactor

ATF (Alternating Tangential Flow)

Alternating Tangential Flow (ATF) is a cell-retention technology commonly used in mammalian cell perfusion processes.

In an ATF system, a hollow-fiber filter module continuously separates cells from a spent culture medium. The cells are retained inside the bioreactor, while the culture medium is perfused, enabling high-density, long-term perfusion cultures.